»CASTING Plant and Technology International« (CP+T) is the leading English-language foundry journal with a worldwide distribution. It covers the entire foundry technology for ferrous and steel castings, as well as non-ferrous metal castings including die casting. Raw and auxiliary materials as well as questions of quality control and environmental protection are included.

The focus is on technical papers from the practice of plant manufacturers, suppliers and foundries.

Short news about new facilities and processes and important events in the foundry industry complete the editorial offer.

Contents of issue 4 - December 2024

CONTENTS

- SAND MANAGEMENT - Understanding and controlling hot sand for green sand molding

- DECARBONIZATION - 62 percent less CO2, 80 percent less water consumption

- FILTRATION - Specific pore design for improved process and quality control

- DATA MANAGEMENT- From data collection to AI control of a foundry

- BINDER JETTING - Slurry-based binder jetting of ceramic casting cores

- SYNTHETIC SANDS - How to increase surface quality and productivity

- SIMULATION - Designing permanent mold castings

- AUTOMATION - Individual robot grippers from the 3D printer

- INDUCTION TECHNOLOGY - Practical energy-saving measures and digital process data analysis

- DATA ANALYTICS - Enabler for top performance in manufacturing companies

Where is the journey going?

The global economy is facing a variety of challenges, particularly following the election of the new US president. Added to this are the requirements for decarbonization. Our industry offers the basis for many processes and products that can provide an answer to the current challenges.

The International Monetary Fund (IMF) expects growth to remainmediocre in the coming years. Despite ongoing geopolitical tensions, the share of global trade in global GDP has barely declined. This could now change: Following the election, president- elect Donald Trump has announced that he would impose higherimport tariffs on key trading partners. Protective tariffs of 25 percent are to be imposed not only on goods manufactured in Canada or Mexico, but also on products manufactured in the USA that use foreign-made parts. If these preliminary products are made in China, a further ten percent will be added. This has far-reaching consequences for global trade flows. And not just for car parts: Due to the likely decrease in trade, shipbuilders and therefore foundrymen of ship propellers, for example, will also be affected by higher tariffs.

Nevertheless, our industry is working on a wide range of solutions for the environmental and technical challenges. You will find convincing examples of this in this issue. For example, simulation of the casting process prevents long development times using traditional trial-and-error methods or energy- intensive sample parts. This allows extremely tight schedules to be adhered to and production to be cost-effective. Another important aspect is data management. Foundries must systematically record their relevant data in order to achieve product traceability and thus lower reject rates.

The switch from cupola to induction furnaces contributes to the decarbonization of processes. We report on such a conversion at Saint Gobain PAM in France by ABP Induction. But even after that, it is important to operate an induction furnace as economically as possible. The article by Otto Junker presents various approaches to this.

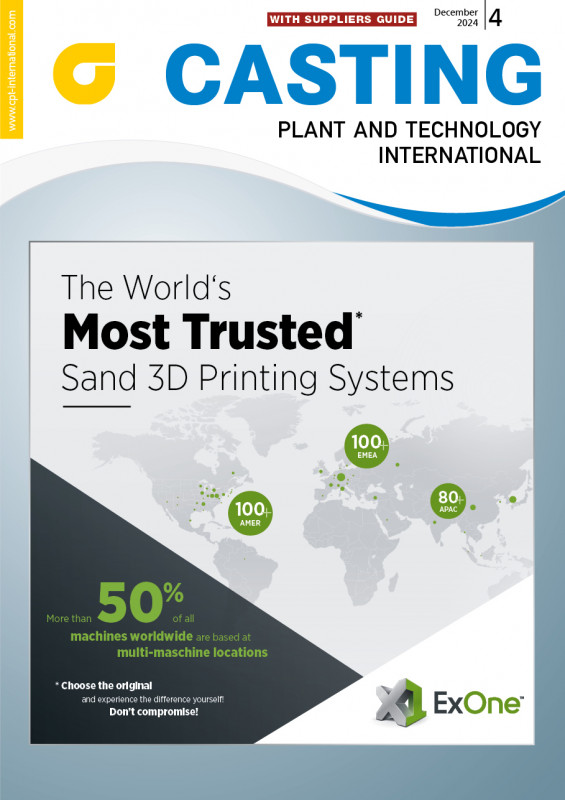

Another topics include 3D printing for individual robot grippers, slurrybased binder jetting of ceramic casting cores with the finest geometries as well as 3D printing for ceramic foam filters. Other articles deal with sand management for controlling and monitoring hot sand in green sand molding, and the effects of synthetic sands on the productivity and surface quality of mold packages and castings.

I wish you an interesting read, a Merry Christmas and a Happy New Year!